NEW USED PARTS ORDERING PAYMENT SHIPPING WARRANTY RETURNS

TECH RESOURCES GALLERY WANTED LINKS NEWS EBAY FAKES

HOME NAMM FEEDBACK TESTIMONIALS CONTACT EMAIL

NEW GUITARS USED GUITARS PARTS

Cracked Neck Repair

This repair is basic woodworking so there's nothing complicated about the job and anybody should be able to pull this off without any problems.

Here is a cracked UVMC neck. This neck was cracked when the guitar hit the floor headstock first and is not the typical crack behind the nut you'll find from over tightening of the nut, although the repair is the same for both. This crack is tough to see as it's nearly perfectly closed so I'll save the multiple views until I spread it. This side shown got some dirt in it at some point so it's a little easier to see the dirty line.

The first part of the job is spreading and gluing. What you'll need is any piece of lumber long enough to mount the neck on, a few clamps, glue, paper towels, water, and a piece of indiscriminate stiff [but thin] clear mylar, this one barely visible in my fingers I cut from some product packaging I grabbed out of the trash can. [Due to organization [or lack of it] the wood and clamps never made the shot ;)] Note that while I prefer Elmer's Carpenters Glue for most glue repairs because it's thicker, I will use Titebond for this job because it is thinner and therefore easier to work deep into the crack.

Time to spread the crack. Clamp the heel of the neck to the lumber, in this case a 1" x 4", and then slowly and carefully clamp down the headstock end to spread the crack apart. Where to stop spreading is a judgment call. Of course you don't want to break the headstock off the neck, but you do want to open it wide enough so you can get the glue to penetrate deeply into the crack. If you hear any creaking or cracking whatsoever STOP. Spreading to this gap there was no sound and no worry of breaking.

Now you can really see the crack which runs from beyond the first fret up to the nut holes and back to the first fret.

Time to glue it up. Run a decent bead down one side of the crack and using your finger pull the glue into the crack to force it down in. You want to work fairly fast as you will have limited time to work with the glue before it starts setting up on you.

Here you can see one side loaded with glue.

Do the other side.

Now that it's worked in I like to go back and do it all over again. Load it up with more glue and repeat as above. I want to work as much glue into the gap as possible.

This is where you use the piece of mylar to work the glue as deep into the crack as you can along the whole perimeter of the gap. It doesn't have to be mylar but it does need to be resilient to the glue and still thin enough to get in deep. If you tried to use a business card or anything else paper based it would instantly turn into a limp noodle when soaked with glue and become worthless. Using this I was able to work the glue up to 3/4" deep into the crack.

After forcing the glue deep with the mylar I will go back and do it all again. Load it up with more glue working it in with your finger, twice. Then using the piece of mylar work as much as you can as deep as you can into the gap.

The crack is now loaded up with glue, and lots of it. It's time to pull the clamp off and let the excess glue ooze out. Alot will come out, but not near as much as you put it. This is about 25% of what went in considering I loaded it with this amount 4 times.

Time to clean up the majority of the mess using a dampened paper towel. [note, I used a toothpick I broke in half to clean the excess glue out of the nut mounting hole]

With it cleaned up it's time to clamp the crack itself. Hard enough to get it as close as possible to flush but you do not want to squeeze all the glue out [if it was possible at this point], the glue is what's going to hold this crack together, squeeze it all out and there's nothing left to hold it ;) [Note that this was a tight gap crack to begin with so the force of the neck closing itself squeezed out nearly all the glue it was going to, leaving very little to come out during clamping] Of course if I used an all metal C clamp and a piece of wood to protect the neck I would get a closer seam, but I would also squeeze out more of the glue and since the strength of the repair is in the glue I'll just use my padded bar clamp and squeeze as tight as possible. Clean off as much extra glue that came out as you can using the damp paper towel. Not wet, you don't want any water diluting the glue, you just want it damp enough to clean the majority of what came out as you're going to sand it all flush later anyway.

After letting it dry for 60 minutes I've pulled the clamp and finished cleaning the remaining glue off. Now you can see how far the two sides of the crack are still spread because of the glue that's in the joint itself. Time to finish the job.

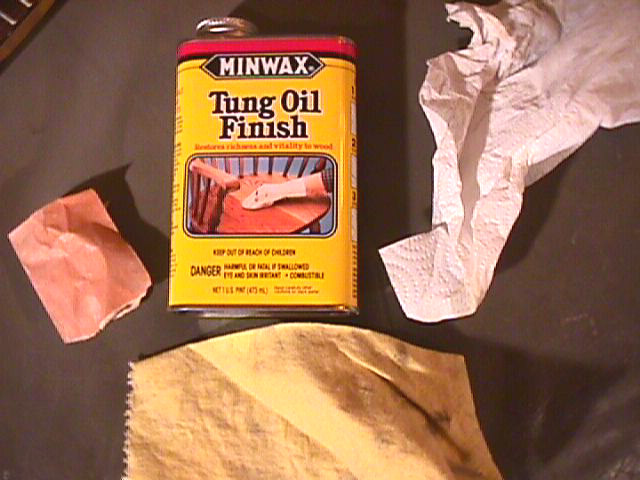

The materials you'll need to finish are 220 grit sandpaper, a paper towel, cloth, and tung oil. [This neck is originally finished in oil. If you're working on a clear coated neck you may want to use an airbrush and the appropriate clear for the type neck you are working on and re-spray the finish on. Although, tung oil will also work to seal and put a sheen on ever a clear coated neck.]

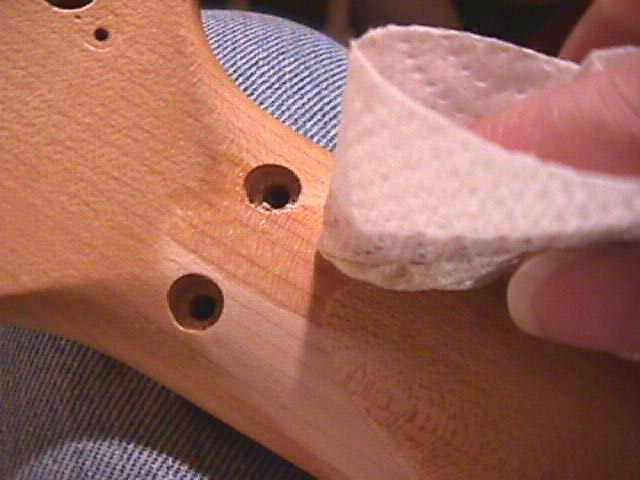

First step is to sand down the high side of the crack. Do not just sand, sand the high side of the neck only. You want to get it nearly perfectly level before you start to sand across the crack line and blend it out to the low side. Of course you only want to sand in the direction of the grain even with 220. Some would opt for a faster cutting 100 grit but a slow and precise job will be evident in the finished product using the finer grade.

Here you can see one side blended and getting close to ready to blend in the other side. Note, only sand until the blend is smooth and complete, you do not want to remove any more wood than is absolutely necessary!

All done and it looks great. Yes it's going to be lighter. Wood darkens with age and an old neck is usually dirty too, but as you can't see, the crack has nearly disappeared ;o}

Take the paper towel and work some tung oil over all the now bare wood. Not alot, a little tung oil goes a long way.

I usually don't leave it on more than a few seconds and then just wipe off the excess and buff till dry and smooth. You can always do it over and over again to build up the oiled finish if you prefer. As you can see this repair looks great. If I had been ultra anal I probably would have finish sanded the dirt off the rest of the headstock too and re-oiled it all just to get a more even look, but this neck does have some small clear coat issues on the face of the head so I'm not going to get ultra picky about trying to make it look perfect. It is a very good repair as you can't see though ;)

The only telltale sign besides the lightening of color in the sanded area is the dirt that was left in the crack that was on this side to begin with.

Of course this repair needs to fully cure for 24 more hours before installation on a guitar, but the repair is now complete and extremely strong. There was alot of glue that was forced deep into the crack to ensure that it will stay closed, probably forever. Typically a glued joint is stronger than the surrounding wood and I would bet money there's enough glue in this joint that if it ever happened again it would crack in a different spot. How much money would I bet? How much ya got, if it's enough I'll break it again to find out ;o}