NEW USED PARTS ORDERING PAYMENT SHIPPING WARRANTY RETURNS

TECH RESOURCES GALLERY WANTED LINKS NEWS EBAY FAKES

HOME NAMM FEEDBACK TESTIMONIALS CONTACT EMAIL

NEW GUITARS USED GUITARS PARTS

This page used to be called sharpening, but that was a was a poor choice of words. Thinning would have been correct and why it's changed.

Knife edges come in all thicknesses and profiles, too thick, too square, too thin, too sharp, rounded off, buggered up, etc. Matching the knife's edge to the stud's groove it rides in optimizes it's ability to freely return to neutral. I give the knives on every guitar I touch attention of some kind, most flat side knives from 92' to 03' will be too thick, most times the curved side is also too thick but sometimes they're have an angled back-cut making them too sharp. Most Edge Pro curved sides are far too thick, while the flat sides range from adequate to too thick. Visually inspecting and comparing to what you see below will give you an idea what, if any, attention your knives need.

If you never perceive your guitar as out of tune then you probably *don't* need to file! If you are troubleshooting a tuning instability problem exhaust every other option listed above before proceeding! If you're having serious sharp return from a trem pull up read on.

Before proceeding any further read the last two paragraphs and follow the instructions, you may find the results adequate enough to stop there.

At perfect tune, in the bar down neutral, the trems are stable as a ROCK. You can abuse

the living Hell out of them and they'll always return to perfect tune. As long as you

don't pullup, and *rest* up. Some you can pullup and the difference in pitch just isn't

enough that most people would notice, and why 75% will never have a clue. But there are

some that return so sharp ANYbody can notice. And still, if you never pullup and leave up,

you'll never notice that either. Only file if the way YOU play leaves you *noticing* it

out of tune. But everybody should install a set of the new studs, they are the best

improvement since Leo thought about putting strings on a plank ;)

A knife edge is a *wear* item. They always have been. Knives are going to get buggered up

no matter what on any trem that's *used*. I've put a nice edge back on plenty of late 80's

Jems that had long hard miles, and gave them another 100,000 miles before the next

overhaul. Everybody that likes to whammy should check their knife edges as a part of

normal maintenance, maybe twice a year, about as often as you should tighten your tuners.

No one should assume they'll last the life of a guitar without maintenance, they won't.

I've seen some trems with flat knives .75mm wide. Way too wide, .5mm is still too wide, .33mm is about the thinnest I've ever filed them to and the .4mm factory edges float extremely well in new studs so use that as a guide. We're not talking about making a steak knife here and you will hear this again, about the width and shape of a butter knife edge. Leaving them wider is always more preferable than getting them too sharp!

***Doing this to a new guitar under warranty will void the warranty of your trem.***

***I highly recommend you do not try and file Double Edge piezo bridges. The lead is very short and any break in that lead and your piezo is dead. It can be removed enough to drop in a set of the redesigned studs but I recommend you stop there. I filed 2 X bridges, it's a very dangerous and precarious position you must get all the "parts" in to do the job. I will not do anymore. It can be fully removed but it requires unsoldering 2 joints on the circuit board, which in itself is not a simple job, have a look and you'll agree.***

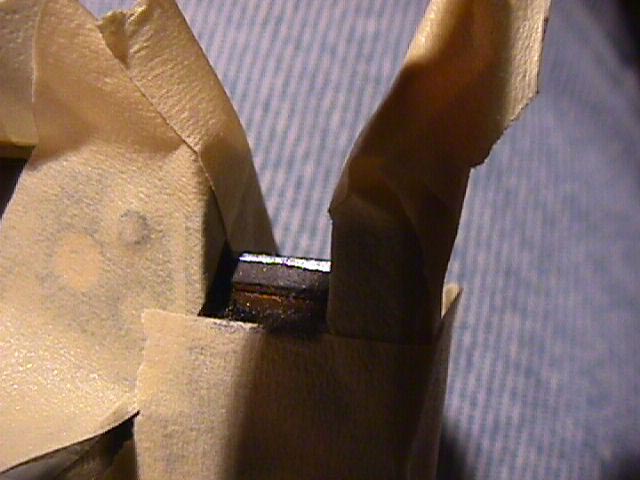

This trem is out of a beautiful 2000' Floral Jem. The 2000's are of superb quality and probably the best Florals made, but unfortunately many have the wider knives. Here's how you fix them. This is probably the best shot I could get of the *flat* edge of this knife. The white reflection of the light is the flat. This one isn't bad, a hair over .5mm, but it's too wide and the corners of the edge are still very sharp.

In contrast the curved sides almost never need attention. This is the best shot I could get to show the very edge of the curved knife. You can see how much thinner and rounded the edge itself is. Seen here by the very dark edge.

Very very rarely will you ever see a curved edge that is too wide, and on the contrary many of them are extremely sharp as they backcut the top edge creating a point - V. Not to say I haven't filled many curved sides too, but I work on LOTS of guitars. If one ever needs attention or is damaged these get filed from the top side toward the arm holder as the holder precludes following the method below. Finish as per below. You can remove the arm holder but it is unnecessary. Since the round bastard file does not cut smoothly like the flat file I'll use a strip of 200 grit wet-or-dry paper to smooth the curved side out after filing. Wrap the paper around the file and get the knife as smooth as possible after it's been worked on.

After you determine the knives need attention you'll of course need good files. These are both from Sears, a 6" Taper File - Slim which is triangular with a tapered end, maximum width 7mm. The round file is a 6" Round - Bastard Cut, maximum 5mm diameter.

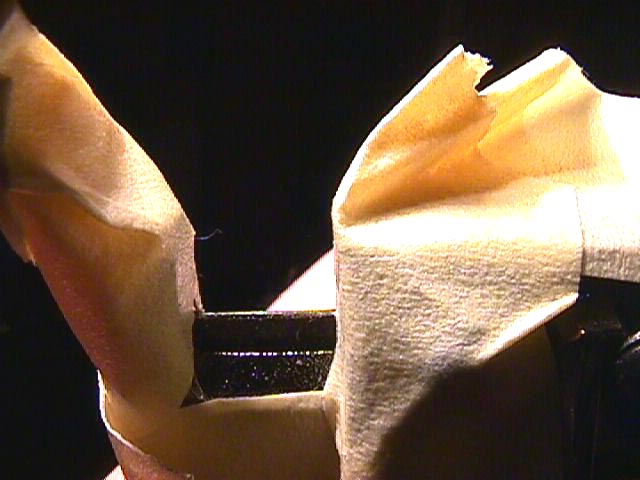

The first step is to mask off the trem with tape anywhere the file could wander into it. It only takes a TOUCH with the file to mar the cosmo finish!!

You want to file from the bottom as that is the angled cut on the knife. Keep the file centered and stable as you use it, it doesn't take much to bite through the masking tape and into the finish. You can see I use my thumb to guide it. Do not push down with your thumb, it's just acting as a wall. You want to file with as even a pressure as possible. If you have more pressure on the right side of the file you'll get an angled cut, center the pressure. I keep my index finger on the top of the file applying the pressure straight down, I just can't take that picture ;)

I've got to update this part. I quit worrying about the bottom of the plate long ago.

The pics show me taping off the bottom of the plate but currently I file the plate right

along with the knife. It allows the angle of the file to be closer to the original angle

of the knife and actually stabilizes the file and keeps it truer when filing. I'll try to

update soon.

You also want to try and keep the angle as shallow as possible. The knives angle is shallower than you can file because of the base plate, which is why I've been filling the baseplate as well as the knife to keep the angle as shallow as possible.

You do NOT want the edge sharp!! The object is to get it *butterknife* sharp. For reference about .3mm and rounded at it's edge. Here is a shot of how much I filed the bottom side.

Now I want to finish this side by curving the corner of the edge. Hard to explain but right now the 'corner' is sharp as the 2 planes meet, the flat face of the knife - and the angle of the side / , where they meet it's sharp and you want to slightly round it otherwise the sharp corner will bite into the post when using the trem. Start with the file at the steepest angle you have been filing and through the stroke increase the angle till you finish perpendicular and filing the face. Not much pressure is needed on the file and it will only take about 4 passes to get the slight curve. Usually I'll just do 2 passes doing a stabbing stroke like a jig saw while I increase the angle to round them off. This is the result, as clear as I can get it to show in jpg.

The top edge is usually crisply sharp also so I'll file just *slightly* from the top just to dull the edge a hair. Just like the last strokes on the bottom side, here I want to file the same slight curve to take the sharpness off. This is the end of that stroke. Like the bottom, usually 4 is plenty but it will depend on how much pressure you apply and how long your stroke. [nasty joke edited] The lighter the pressure and the smoother you will leave the steel, preferable! I can't do either and take a picture ;)

The end result is a slight U shaped edge instead of the box shape it was in when I started, butterknife width, butterknife sharp. Optimal would be anywhere in the .3 - .4mm wide range and if in any doubt, file a little, reinstall the trem, and test. You can always pull it out and trim a little more but you can't put the steel back on the edge. If you get them too thin you'll have to file it back blunt again which could remove several years of life from your knives.

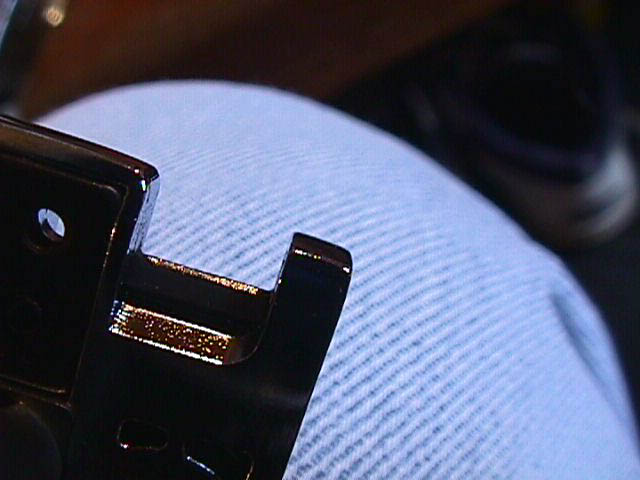

This trem is ready to be reinstalled but it cannot be installed on the pinched V posts that came originally on this guitar. I'm installing a set of the New Cut posts, otherwise the best knife edge in the world still won't give you stable tuning when using the trem. This is the original post on the left and the New Cut post on the right, barely noticeable is the groove around the New Cut for identification, between the V and the threads. It's very tough to see but the bottom angle of the V on the original post is at a smaller angle making the V tighter. You can also see the very 'point' of the V on the New Cut post is much more open.

To make the setup easy after swapping the posts I'll preset the depth of the set screw on the New post by lining it up with the old post and set screw. Of course I removed the original posts without touching the set screws. Now when I put the trem back in the action height hasn't changed. The guitar was actually still in almost perfect tune which is quite rare because the depth of the grooves are different on each different run of studs. Usually you'll have to reset the trem angle and check the intonation. But the most important part, the tuning remained stable under whammy dives and bottoming out pullups! Job done.

**UPDATE** - I took alot of heat about filling knives and recommending the rest of you could improve your performance if you were having problems in this area. Well, I'm feeling quite vindicated now. These are close ups of the knife on an 03' Edge Pro bridge. Notice that Gotoh is now rough grinding both edges of the knife to thin it out before pressing it into the baseplate. Fairly crude but they're performing extremely well [if you've upgraded the new Edge Pro's degradation to non locking studs] but can definitely use a little more thinning and cleaning up. The curved side on most Edge Pro bridges is far too wide and I will have to add more to this page on how to file the curved side.

Even with the knives filled perfect you may have some sharp return after a pullup. I scratched my head trying to get over this last hump for a long time and tried oils and grease to no effect. The secret ingredient - Chapstick Lip Balm. This is a very waxy type grease that will take a 95% trem return and instantly make it a 99%, and typically take a 98% and make it 100%. I would highly recommend this as a first step before any filing on the knife edges of even stud replacement, it's just that effective. I'm not sure how well this product is distributed around the world so you international boys might want to hit Yahoo Shopping and try and find somebody that will ship a couple sticks overseas [a couple so you can share it with your mates!]. I may even start stocking it LOL [Sidenote, I couldn't stand the stuff when my wife would put it on her lips, nothing worse than that big old slippery greasy kiss [except lipstick, which leaves you looking just as sexy as her after a smooch] but considering the results it gives on trem fulcrums I'm now thinking about buying stock in the company!]

With the guitar in perfect setup [including the stud's set screws locked] use your 4mm wrench to spin the stud 180 degrees [lefty loosey!]. Take a toothpick and work the Chapstick until you have a small ball of it at the tip.You want to spread and deposit this ball in the groove of the stud exactly opposite the knife [it's been turned 180 degrees so when you turn it back it will be at the knife] and just a tad before exactly 180 to guarantee the knife gets coated also. Spin the stud back 180 till the set screws seat and lock. Do both curved and straight side knives. When done whammy a bit to spread the coat everywhere the knife will make contact. With your last motion a bar down and rise to neutral [this is the only way you should fine tune a guitar] fine tune until the instrument is in perfect tune. You should now enjoy superior return from a straight pullup of the bar with all strings returning to near perfect tuning.

Thanks to Gary Brower for this tip, he's been using it on Chromeboy for years and it's always kept a smile on Joe's face ;o}